Total Surface Quality – From start to finish

With its latest generation of satos TSQ machines, Steinemann has laid the groundwork for fully integrating the sanding line into a production process.

Steinemann aims to continue asserting its position as technology leader in the future.

To this end, we are concentrating our efforts not only on steadily advancing our machines and abrasives, but also on helping our customers to integrate their sanding lines and optimize their overall sanding processes.

The satos TSQ represents yet another milestone, because even the standard version meets all the technical requirements for a fully integrated and automated sanding process.

To see the set-up of our sanding line and find out more about how the various components interact, click here.

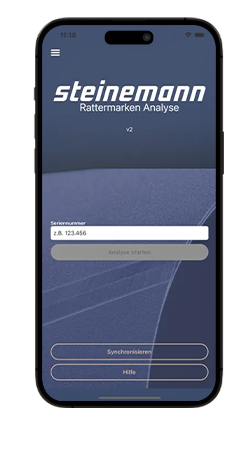

Have you already downloaded the Steinemann App?

Chatter marks are caused by vibrations in a sander. Vibrations can be generated, for instance, by the joints of the sanding belts, the contact drums, guide rollers or tension drums. The cause can be determined based on the distance between the chatter marks and several types of process and machine data. The app identifies the cause and displays the result. For this calculation, the app requires data on the geometry and process of the wide belt sanding machine. Such data naturally is stored in the app for most Steinemann machines and automatically incorporated in the calculation based on the machine’s serial number. If the machine number is not stored in the app, users have the option of configuring their own machine. This way, the app and the integrated calculation can be used for all sanding machines of similar design.