Drum systems/repairs

Steinemann drum systems for the production of superior surface results. The high-precision production techniques used to make our drums and the virtually vibration-free, low-wear interplay of the overall system ensure consistently high panel quality.

What makes our drum systems unique:

Sophisticated drive decoupling

Reduction of vibrations

Forged drum ends

Grooving and Arctech® coating

Beating design

Lubrication design

At a glance:

Our calibration drums figures speak for themselves:

- Radial runout accuracy of 0.02 mm

- Balanced to exactly 5 grams at 2,000 rpm

- Drum cylindricity of 0.015 mm and around 0.005 mm for bearing seats

We offer a 24-month process reliability guarantee on:

- Panel dimensional tolerances

- Target surface finish

- Machine availability

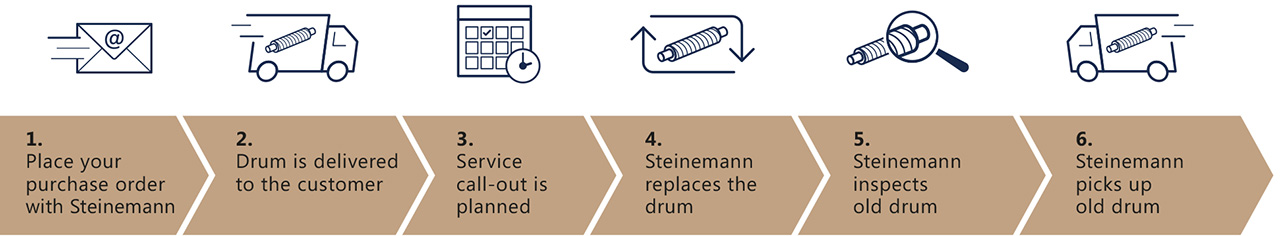

Our contact drum exchange program for Europe:

Your benefits:

Product

- No spare drums need to be held in stock

- Guarantee automatically extended by 24 months

- No capital spending on new drums needed

- High process reliability

- Consistent, trusted Steinemann quality

Service and cost savings

- On-site installation included

- Transport included

- No transport costs

- No customs formalities

- All-inclusive Steinemann service

- Plannable costs

- Reduction to TCO

Note

If you have enquiries or questions, please contact our experts:Spares & Consumables

+41 71 313 51 51

+41 71 313 52 52

spareparts@steinemann.com