BQC – BOARD QUALITY COCKPIT

The process control system for a fully integrated, automated sanding process.

BQC – the process control system for a fully integrated, automated sanding process.

The combination of the satos family and BQC represents a giant step towards our ultimate goal: the fully automated sanding process.

As an autonomous software program that is independent of the machine software, the BQC can be used to network all sanding line peripherals. Interfaces to external and internal systems make it easy to collect all relevant data.

Data from the entire sanding process is analyzed in BQC to derive recommendations for action that result in improved quality and efficiency, plus cost savings.

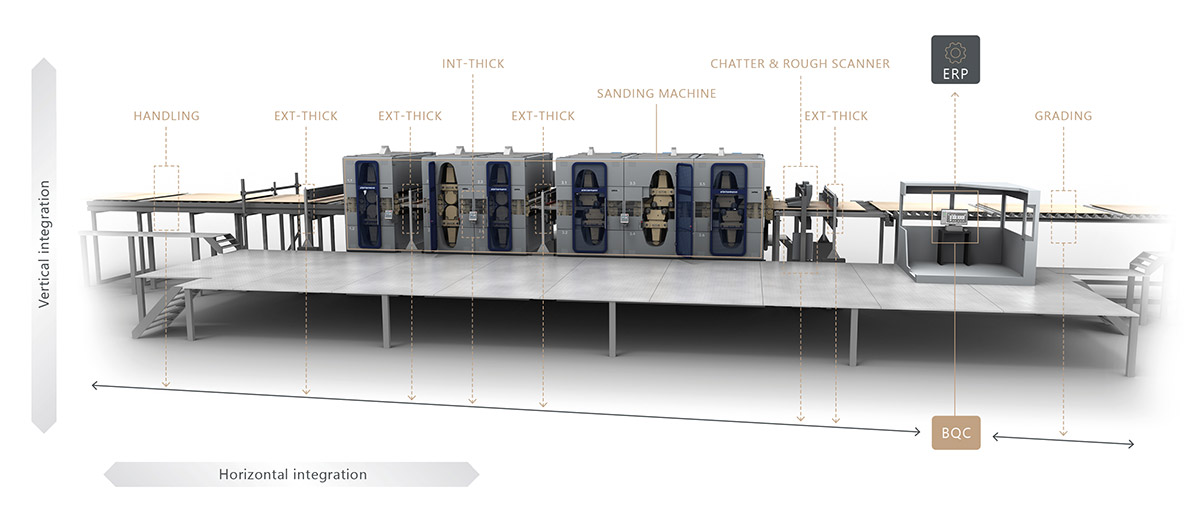

Integration of the entire sanding line.

The interlinking of all of the sanding line units required offers a high level of process transparency.

The horizontal integration involves connecting selected finishing line participants with BQC: BQC then gathers all of the data to provide real-time monitoring of the sanding process. Potential benefits increase as additional units are interconnected with BQC.

As one example, an interface to thickness measurement permits monitoring of the optimum sanding machine settings based on the actual thickness of the panel before, in, and after the sanding machine.